Nintendo switch wireless charging grips - Powercast

Four injection molded parts fasten with thread-forming screws to form the grips. Curved light pipes redirect light from the joycons to the top for player interaction. The powercast logo is screen-printed on the top of the grips.

The powercast RF wireless charging technology allows the grips to be charged over several feet by their Powerspot wireless power transmitter.

Electric scooter charging station - SKA Custom Robots & Machines

Users can lock and charge their electric scooters using this modular charging stations. Scooters are locked in place with a solenoid lock located in the charging post, activated by an application. A retractable charging cable located next to the lock can fit any popular electric scooter. Large marine batteries housed in a weather resistant enclosure provide the power for nearly a week of charging.

The station doubles as a location for scooter collectors working for electric scooter rental companies to charge overnight.

Freelance mechanical design

At Deeplocal I worked alongside a team of talented engineers, designers, and creatives to create novel and meaningful experiences for a Fortune 100 Company. I was responsible for the rapid prototyping of the electromechanical system of a robot, fabrication of the robot and its subsystems, and improving the designs of the subsystems for manufacturing. I added to my experience in design, PCB prototyping, 3D printing, laser cutting, machining, woodworking, and programming.

TrashBot - CleanRobotics

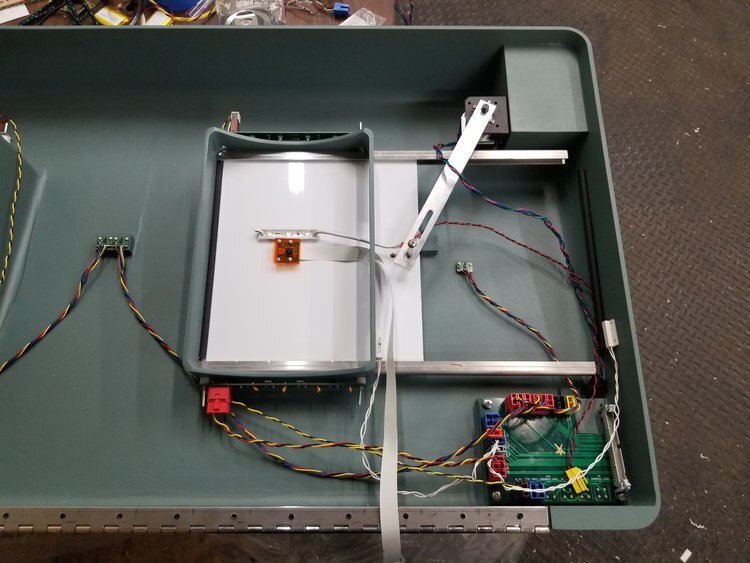

TrashBot is a robotic trash bin that uses AI to sort landfill waste and recyclables. Over 18 months, I oversaw the design, development, manufacturing, assembly, and distribution of the product.

When item disposal is detected by an array of IR transmitters, the lid is closed by a stepper motor driven pin-slot mechanism. Items are identified as either landfill waste or recycling and pushed into the correct bin by a stepper motor assembly. Time-of-flight sensors located in the top measure the fullness of the bins.

The chassis of the TrashBot consists of an easily assembled frame consisting of four weldments. The ABS plastic top is fixed to the frame. Brushed stainless steel panels make the body rugged while maintaining a pleasing aesthetic.

Senior design - Fenner Precision

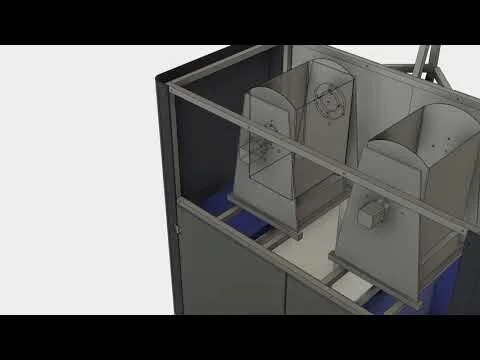

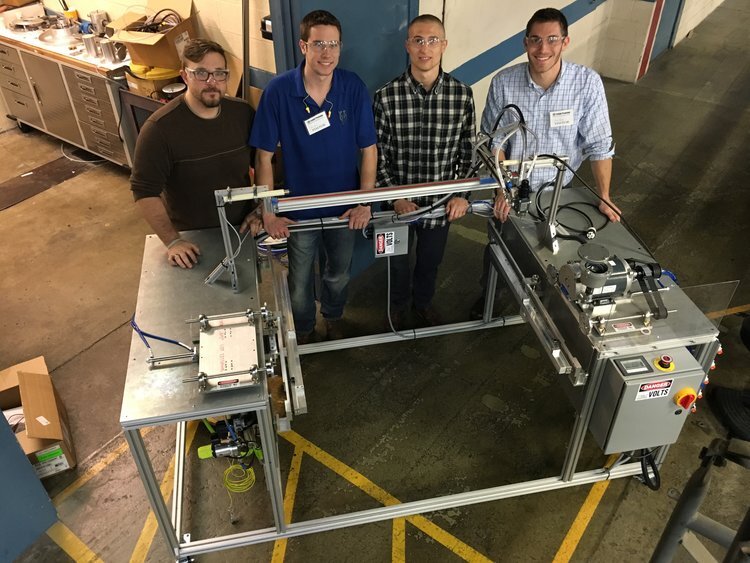

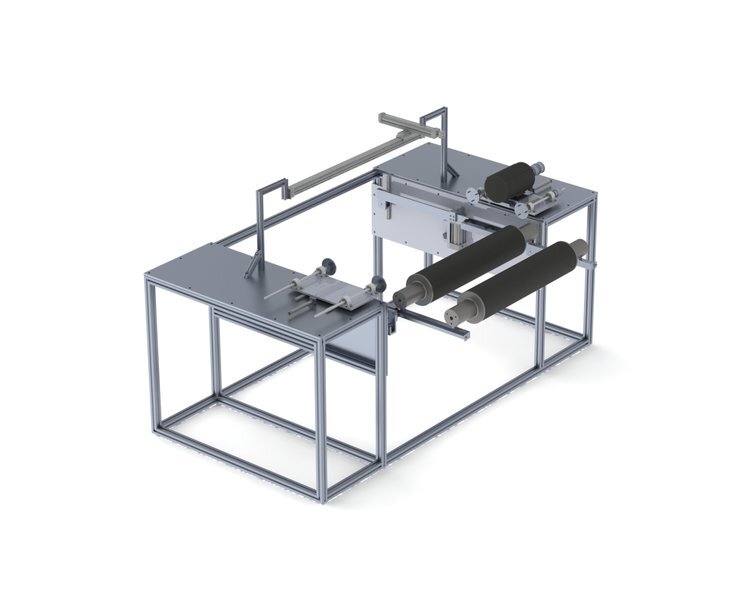

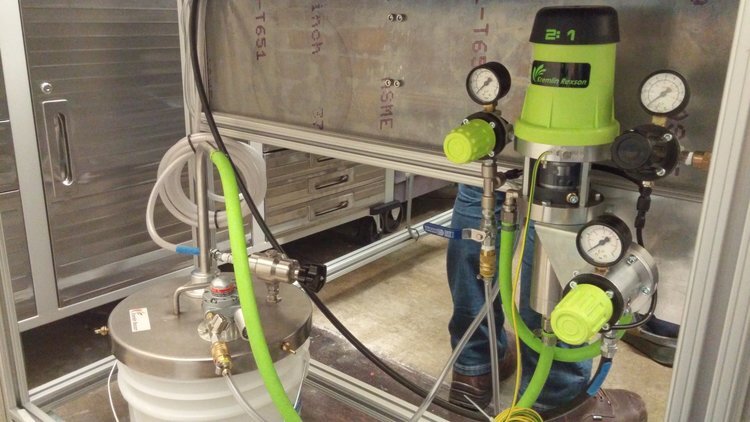

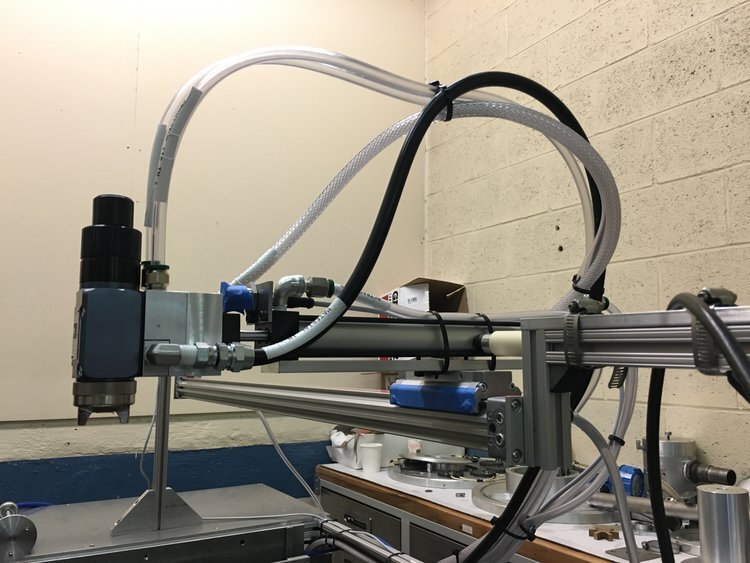

We designed and fabricated an automated adhesive delivery system for digital printing rollers that minimized operator time and manual input, improved adhesive coating quality, and increased the speed of the process. In 12 weeks we successfully delivered a functioning prototype to enter testing.

Large digital printing rollers are raised into place by pneumatic linear actuators. A motor assembly engaged with the rollers then rotated them while the gantry traversed each roller, coating them in a thin adhesive film. The motion was controlled by a number of limit switches and solenoids connected to an I/O controller which we programmed with ladder logic.

The design was especially successful in achieving the specific adhesive coating thickness tolerances, and drastically decreased the number of necessary worker inputs of the coating process.

Vibrational biorectors - Xinqiao Jia Vocal Fold Reasearch Group

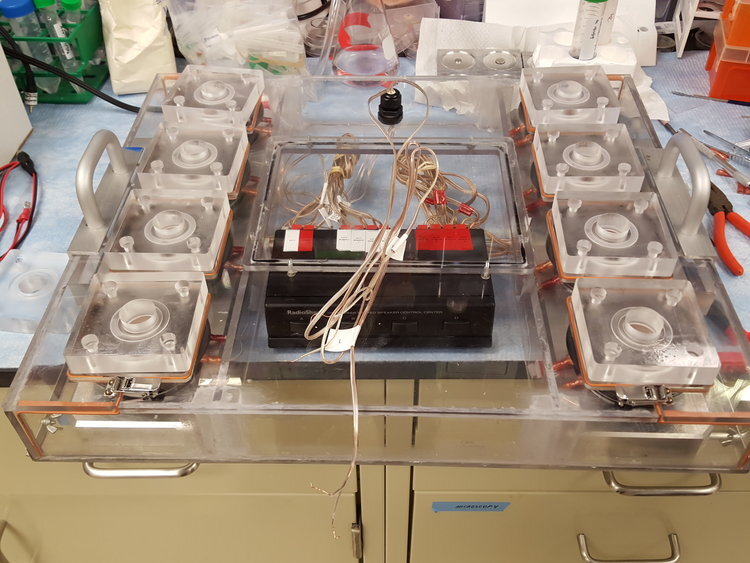

At the University of Delaware, I designed and machined two vibrational bioreactors for a biomedical research team. The bioreactors consisted of eight speakers housed in pockets machined into two large aluminum blocks (one on each side of the bioreactor). An acrylic block is mounted to the face of each speaker, with another block bolted on top. A silicon membrane is sandwiched between the blocks. The stem cells are suspended in a saline solution on the membranes and vibrated by the speakers.

I gained significant experience in SolidWorks and nearly 100 hours of machining experience.